DESIGN AND MANUFACTURING PROCESS

The manufacturing process: ready-to-assemble furniture, from raw material to shipping

Web Furniture makes furniture in ready-to-assemble kit form for on-line sale and large-scale retail chains, distinguished by Italian design and devised for easy assembly.

The careful organisation of what we do and how we do it, along with our ability to adapt to customer requests and our unique Italian style, which is recognisable in all products, have over the years ranked us as one of the leading European players in the production of furniture for large-scale retail chains and e-commerce channels.

A flexible organisation catering to the customer’s needs

Our watchword is “FLEXIBILITY”: our customers know that we will always do everything to satisfy them. Tell us what you need, the way you do business and the kind of furniture you’re looking for. We will adapt as much as possible to your requests and can advise you on the furniture models and services that best suit your needs.

We have a very extensive catalogue of products in stock, available for immediate delivery, and many more can be produced with very short lead times. In special cases, where none of the pieces in our range meet your requirements, we are willing to produce new items of furniture, designed and engineered together with you.

On request, our services are also customisable, thanks to a logistic, industrial and technical-administrative organisation capable of meeting the diverse needs of a varied and international clientèle.

All at competitive prices, always.

The production of our furniture, step by step

Our process involves a sequence of steps, ranging from the initial concept of a new design through to delivery (directly to the end consumer, to our customer’s carrier or directly to their warehouse), to an efficient after-sales service.

The design concept

Every item of Web Furniture is conceived and designed in Italy. Our design is anything but standard, but rather boasts a strong stylistic characterisation, which makes our products highly recognisable on the market.

Read More

The shapes, the colour combinations, the proportions of the furniture are all studied thoroughly. Our designers are constantly updated on global trends, as well as on specific ones in the various areas of Europe.

Design 100% made in Italy makes our furniture modern, elegant and packed with sophisticated details.

Design planning

Every new furniture concept is first “sketched” on paper by our designers: hand drawing is the fastest way to capture the creative intuition of the moment.

Read More

Using a render, the “sketch” is then transformed into a three-dimensional image for a more realistic evaluation of the design and the various finish possibilities.

We often share the design with some of our historic customers to get their take and feedback before moving on to the next steps.

Once approved, we go directly to the industrialisation phase, with the technical development of all the product components, the packaging diagram and assembly instructions, and then on to the production phase.

In some cases, a sample is initially made so that it can be tested and offered to the prospect before approval.

Panel processing

From the final design, we go straight to furniture production.

The process starts with the processing of melamine-covered particle board panels in various sizes and thicknesses, which are cut, edgebanded and drilled according to the design of the kit in order to be easily assembled by the end user.

Learn more about the panel processing steps

The main processes they undergo are:

- Sizing. The particle board panels are sized using specific cutting systems to obtain smaller panels from which the various parts of the cabinet (doors, top, side panels, base units, etc.) can be obtained.

- Squaring and edgebanding. The sized material is adjusted to the final size with accuracy to the nearest millimetre and then edgebanded on the sides. The edges can be of various heights, depending on the thickness of the semi-finished product, and various colours, either in a glossy or matt finish, to match the panel.

- Drilling. Using numerical control machines, according to the design technical drawings, holes are drilled for the insertion of hardware. The automatic drilling machines guarantee the utmost precision and this makes for the perfect assembly of the various components during the assembly of the item of furniture by the end user.

- Shaping and painting. Sometimes, additional machining is required to complete certain parts of our furniture. Shaping allows us to achieve semi-finished products with specific shapes, such as curving, rounding and more. The painting process, which involves an extremely rapid UV “veil” process, gives the furniture a perfectly uniform glossy lacquer.

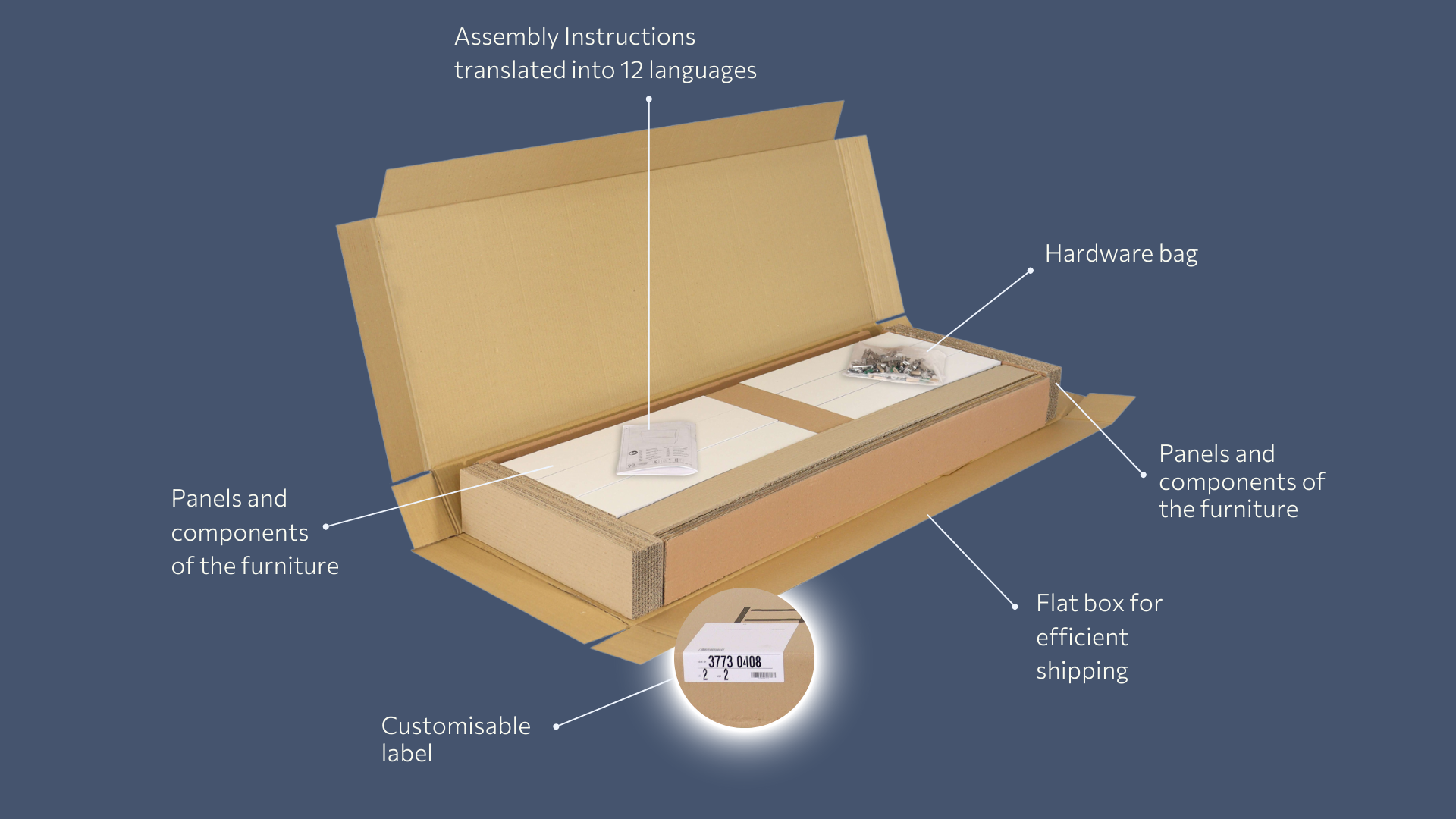

- Packaging the kits. Each furniture component is carefully packed in flat cardboard boxes for easy handling and shipping. The boxes also contain hardware kits comprising hinges, handles, assembly accessories and the assembly instructions.

- Quality control and assembly test. Quality control is carried out throughout the manufacturing process, from start to finish. Our quality-team

applies the procedures of the ISO9001 system and makes sure the quality standards are met as required by the international standard to ensure an impeccable end result, both from a product and process perspective.

A complete assembly test is performed for each new production batch.

Furniture packaging and shipping

In some cases, once production batches have been packaged, they are immediately shipped to the customers who commissioned them. In all other cases, they are stored in our warehouses and made available for immediate delivery

Read More

Packaging is functional to the various distribution channels. We offer a variety of customised labelling and shipping options, reinforced packaging for dropshipping, or customised mixed product pallets for cross-docking.

Furniture shipping for e-commerce businesses or large-scale retail chains can be under our responsibility or that of the customer. We deliver to almost anywhere in the world very quickly, using different means depending on various needs and specific situations.

The assembly kit, fully sustainable

We are well aware of the modern needs of the market: the logistical needs, the shipping criteria in various countries, the demands of simplicity and immediacy that today’s consumers all share. That’s why we take great care in creating furniture kits that are as functional and efficient as possible.

Our products are prepared for delivery in flat, easy-to-handle cardboard boxes, designed to take up as little space as possible and be easily transported. The packaging is also designed to ensure the contents remain intact during shipping.

It contains various accessories, including hardware and clear, user-friendly assembly instructions in 12 languages.

After a long and careful planning process, we have developed our 100% green packaging: zero polystyrene with new cardboard inserts which replace all former polystyrene whilst preserving the efficiency of our packaging and furniture kit.

Even the hardware bag is now 80% recycled!

SERVICES

Not only the supply of made-in-Italy furniture: special services

To our customers, we offer a very different range of logistics services designed to satisfy their needs for made-in-Italy furniture and to meet the needs of the market, even on minimum order quantities.

The level of service and costumer care we guarantee is one of our main pluses and a very relevant factor in retention.

Dropshipping

We are organized to dropshipping our furniture. In addition to having a high stock of products always in stock, ready to be shipped, we provide the service of custom labeling with the ability to enter any data including the address of the final recipient. Dropshipping can include reinforced packaging upon request, which provides additional external protection of the packaging.

Cross Docking

We are organized to fulfill multiple orders from our customers with mixed products and custom labeling, ready to be shipped quickly from their stocks without additional warehousing. This is a great way to distribute our furniture kits while saving on logistics costs.

After-sales support and spare parts

In after-sales support, each request for one or more product components is processed within a maximum of 12 working days, and The customer can find the relevant codes for placing the replacement order on the assembly instructions.

CERTIFICATIONS

Our certifications

To give systematicity to our efforts, we decided to undertake some certification paths.

Web Furniture is available to supply FSC certified products upon request